Water glass casting process

Water glass casting is one of investment casting process, in which water glass is added into the molding materials in proportion and then gets stirred and mixed for 6-8 min, then grind into “ sodium silicate-bonded sand”. Then the sand is put into the mold boxes in which CO2 has been much blown into. CO2 starts the chemical reaction with the water glass to from the silica gel which hardens the sodium silicate-bonded sand.

Why choose water glass casting for your customized parts?

- The water glass casting parts is the most cost-effective casting process with short shell making cycles, which helping you to cut a lot costs.

- Compared with silica sol casting parts, water glass casting components is with large surface roughness and low dimension accuracy.

- The surface quality of investment water glass casting parts is poor, so it is mainly used for carbon steel and low alloy steel castings. And the silica sol precision casting is mainly used for high-alloy steel and stainless steel products.

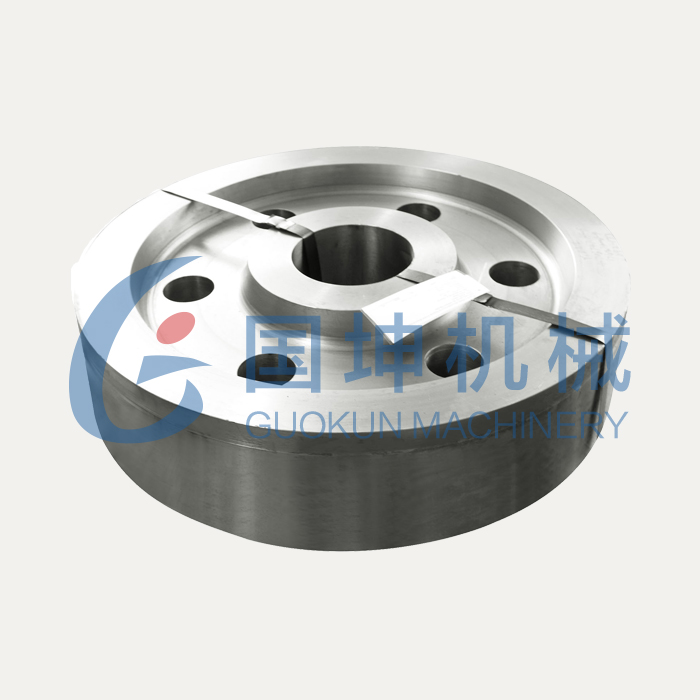

Application: China water glass castings is widely applied throughout all kinds machinery, such as automotive castings, engineering machinery casting, agricultural casting parts, motor casting components, elevator casted parts, mining parts, earthmoving machinery casting components, construction machinery casting parts, marine & ship casting, pump fittings, hydraculic cyclinder castings, valve casting spare parts and various metal casting.

Baoding Guokun Machinery Co., Ltd is A high quality China foundry, mainly manufacture the investment casting, precision casting, lost wax casting, silica sol casting, resin sand casting, green sand casting, shell mold casting, hot forging and cnc precision machining process for all your needs!