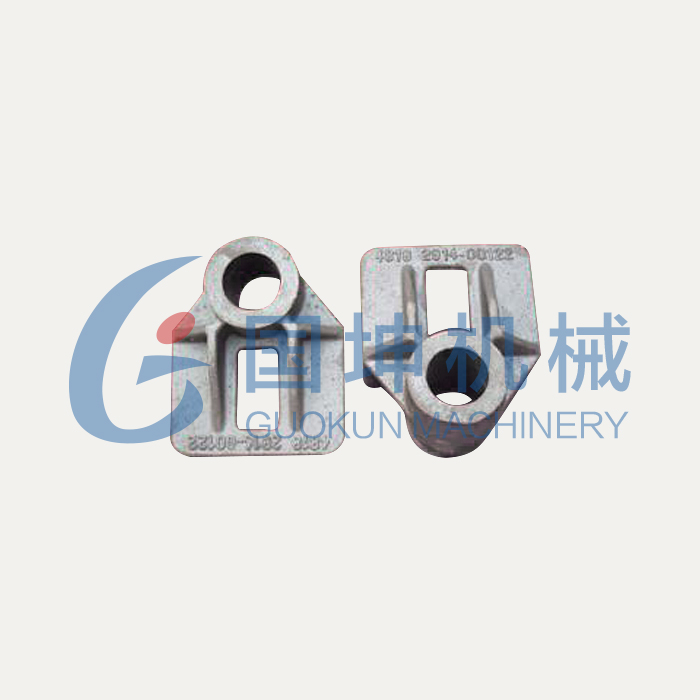

Vacuum Casting Aluminum Parts

Baoding Guokun Machinery can supply you different silica sol vacuum casting process and precision machining services for you. The silica sol vacumm casting process is usually used for thin-wall thickness aluminum components. We even can produce the 1mm thin thickness components.

All of our silica sol vacuum casting components can be served pump and valve industry, mining, engineering, agriculture equipment, truck, motor, marine, etc

We also can supply you other casting process for various casted components.

| Material | Carbon steel castings, alloy steel, stainless steel, wear resistant steel casting, gray iron, ductile iron, nodular iron, malleabe iron, aluminum casting, brass or bronze, etc |

| Casting process | 1. Sand casting, resin sand casting, green sand casting. Investment casting, Lost wax casting or precision casting, water glass casting, silica sol casting3. Die casting, Low pressure casting, Permanent casting, gravity casting

4. Centrifugal casting |

| Machining process | Machined casting parts, machined forging parts, rough machining or precision machining, CNC turning,milling, drilling, tapping, grinding, boring parts |

| Application | Food processing parts, Sporting Equipment, Mining casting parts, Pipe fittings & pump parts ,Automobile, truck, bus parts, Oil & gas casting, ….. |

| Heat Treatment | Normalizing, Tempering, Quenchining |

| Surface Treatment | Polishing, Plating, Painting, Anodizing, Powder coating, sand blasting |

| Dimension Tolerance | CT5-CT13, machining tolerance as per drawing |

| Packaging | Wooden case |

Please email your drawings of Vacuum casting, silica sol vacuum casting, thin-wall aluminum castings, thin thickness aluminum casting, thin wall casted parts, aluminum casted components, aluminum casting parts, China aluminum casting factory to gina@guokuncasting.com or call us 86-18132789710.