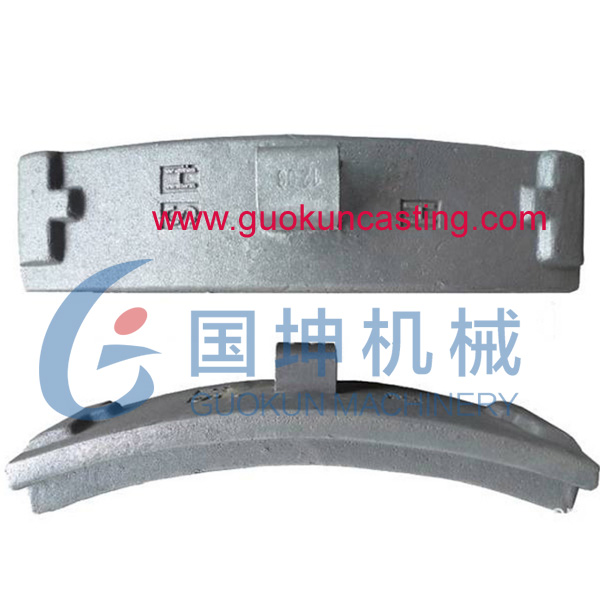

A base tie plate, also called sole plate or baseplate, is a piece of plate made by steel used between the rails and sleeper ties in order to enlarge the bearing touching area and maintain the rail in right gauge all the time. For wooden ties, a baseplate is always fixed with rail spikes or track bolts in holes on the plate

Types of tie plate:

1. The tie plate can be either casting iron or casting steel, depending on the load and the type of rails. Cast iron can be the welded or fabricated type, depending on the customers’ requirements.

2. The double-shoulder type is currently used. Older single-shoulder types were adaptable for various rail widths, with the single shoulder positioned on the outside (field side) of the rails.

Baoding Guokun is a Chinese casting foundry with more than 15 years of producing and exporting experience, which specialized in all kinds of rail fastening systems,rail joints,rail clips,dog spikes,track bolts,tie plate,rail anchors,rail pad,rail clamp,rail shoulder,rail turnout,railroad casting, railway casting component, train casting parts, etc

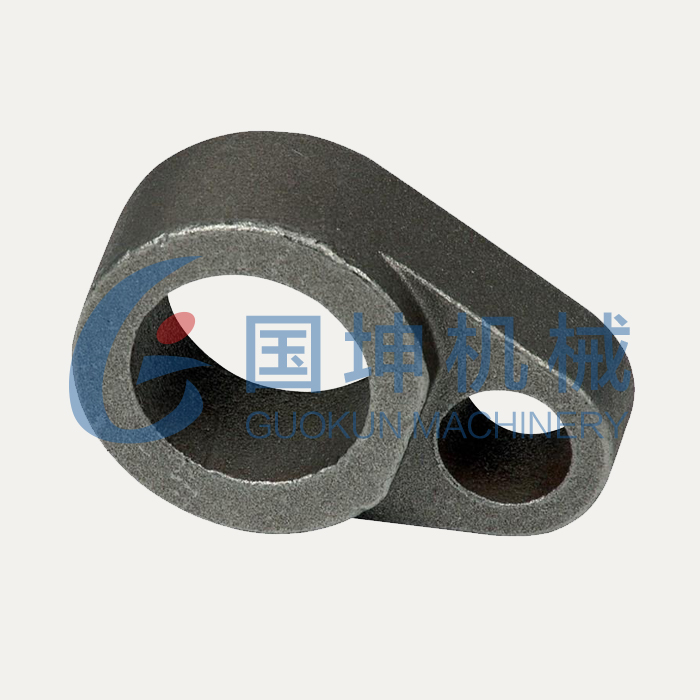

Sand casting is used to produce a widely variety of metal components with complex geometries. These parts can very greatly in size and weight, ranging from a couple ounces to several tons. Some smaller sand cast parts include components as gears, pulleys, crankshafts, connecting rods, and propellers. Larger applications include housing for large equipment and heavy machine bases. Sand casting is also common in producing automobile components, such as engine blocks, engine manifolds, cylinder heads, and transmission cases.

Investment casting process or precision investment castings, also named lost-wax casting, making parts from molten metal, usually carbon steel, alloy steel, stainless steel, special steel, aluminum, brass and copper, etc. Usually we offer two different investment casting process, water glass casting and silica sol casting process.

If you have similar inquiry, please contact gina@guokuncasting.com to get the competitive prices!