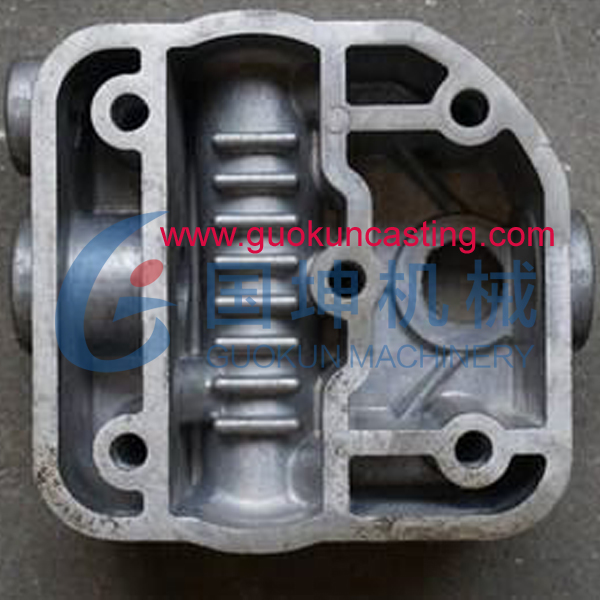

Thin wall aluminum casting

Baoding Guokun Machinery Co., Ltd and Baoding Guokun Export and Import Trading Co., Ltd can produce variouscustomized aluminum die casting parts, which are mainly served for power industry, automobile parts, furniture components, valve castings, pipe fittings, mining casting, truck parts,etc

Die casting process is a metal casting process that is characterized by forcing molten metal under high pressure into a mold cavity. Compared with sand casting, investment casting process, die casting process is famous for high production speed, high accuracy products and fine surface finish. Actually, the die casting has a lots of advantages and benefits as follows:

- The dimensional accuracy is excellent, which can achieve the die casting tolerance CT 6 or CT 7 according to ISO 8062.

- Suitable for small and complex thin-walled parts.If need simple aluminum alloy die casting parts, we advise to use gravity casting process.If need large and thin-wall thickness components, it is better to use low pressure die casting.

- Low unit price in comparison to gravity die casting or sand casting.

- High production speedsCompared with sand casting or investment casting, the production speeds of die casting products is very high.

Die Casting alloys we can offerred

- Aluminum alloys, such as ADC10, ADC12, A380, A360, 413, 383, B390, etc

- Zinc alloys, such as Zamak

- Magnesium alloys die casting

If you need thin wall aluminum castings, thin wall aluminum casted components, thin wall aluminum die casting, thin wall aluminum sand casting, thin wall aluminum die castings, please do not heistate to contact us.