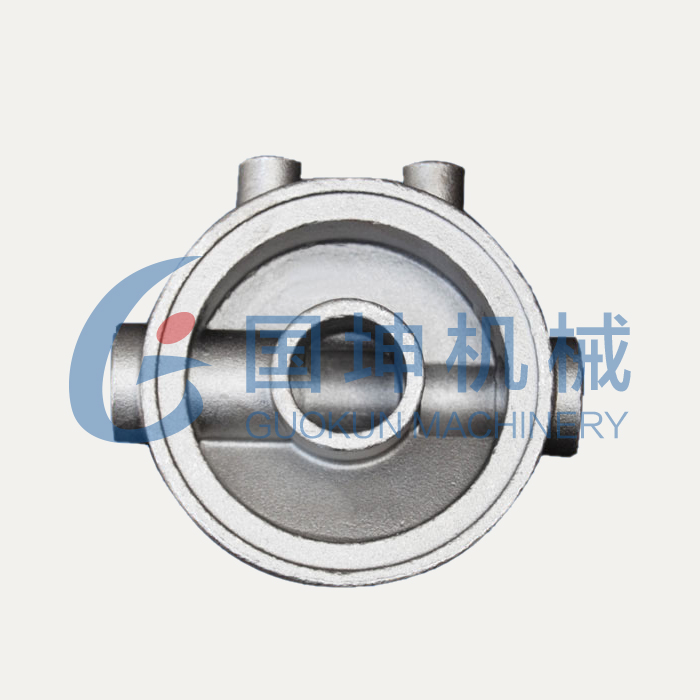

Shifting Yoke

Baoding Guokun can specially produce casting parts, forged parts, machining components widely used in railway & train, auto parts, valve & piping, mining, heavy engineering, industrial engineering, engineering & construction. If you need any mechanical components, please contact gina@guokuncasting.com or call us via 86-18132789710.

More than 20 years’s trading experience and professional production equipment and tester (CMM instrument, X-ray testing, Ultrasonic Testing, Slat spray tester, harness tester, tensile tester, etc) is our advantage.

| Material | Ductile Iron,Casting Steel |

| Process | Investment Casting +CNC Machining(if Need)+surface Treatment |

| Quality Inspection | 100% Strictly Tested |

| MOQ | 100kg |

| Use | Pipe Fitting,Mining,Automotive,Machinery Parts |

| Size | Customized or Acoording with your Drawing |

| Package | Plywood Carton and Pallet |

Investment casting advantages or benefits

- Almost any metal can be casted, such as stainless steel, carbon steel, alloy steel, wear-resistant steel, aluminum alloys, bronze alloys, brass alloy investment casting, alloy castings, zinc investment casting, etc

- Excellent Surface Finish: 50-125 uin, much better than sand casting process

- High Dimensional Accuracy: Water glass casting process’s tolerance: CT6-8; The casting tolerance for silica sol casting process is CT4-6

- NO flash or parting lines: Compared with Hot forging or drop forging process, the precision investment casting process is without no flash and parting lines.

- Little need for secondary machining

- Can produce complex shapes

If you need shifting yoke, casted shifting yoke, casting shifting yoke, investment casting shifting yoke, wheel shifting yoke, mining shifting yoke, engineering shifting yoke, steel shifting yoke, alloy steel shifting yoke, carbon steel shifting yoke, forging shifting yoke, forged shifting yoke, shifting yoke company, shifting yoke factory, China shifting yoke, please mail to gina@guokuncasting.com or gina.guokun@gmail.com