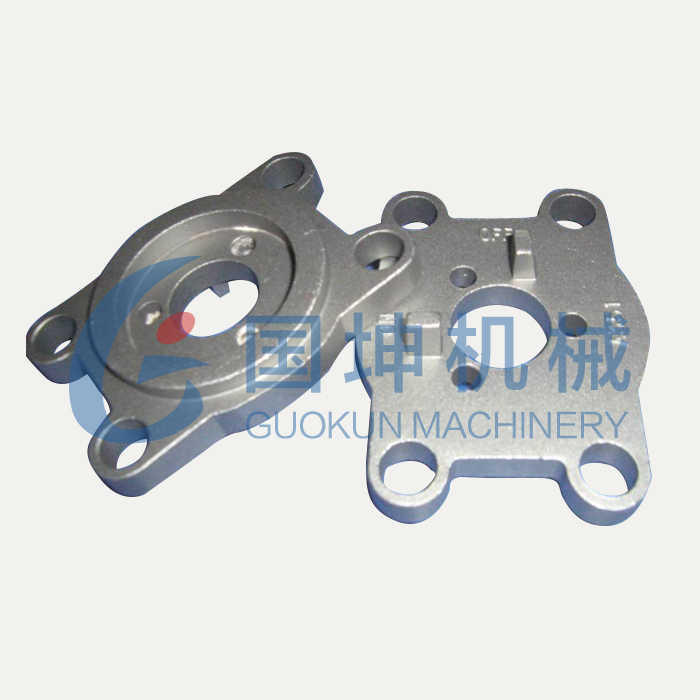

OEM Investment casting China manufacturer of custom casted parts for industrial engineering, pump, valve & pipe fittings, furniture, oil & gas, agricultural spare parts, mining & crusher components, metal hardware, etc

Investment casting advantages or benefits

- Almost any metal can be casted, such as stainless steel, carbon steel, alloy steel, wear-resistant steel, aluminum alloys, bronze alloys, brass alloy investment casting, alloy castings, zinc investment casting, etc

- Excellent Surface Finish: 50-125 uin, much better than sand casting process

- High Dimensional Accuracy: Water glass casting process’s tolerance: CT6-8; The casting tolerance for silica sol casting process is CT4-6

- NO flash or parting lines: Compared with Hot forging or drop forging process, the precision investment casting process is without no flash and parting lines.

- Little need for secondary machining

- Can produce complex shapes

Investment casting material

Stainless steel investment casting, silica sol casting, such as 316, 316L, 304, etc

Carbon steel investment casting, lost wax casting, water glass casting, such as 1045, 1035, 16Mn, ZG35, etc

Alloy steel investment casting, precision casting, such as 4140, 4340, 8620, 8630, etc

Brass and bronze investment casting parts

Please send your drawings to gina@guokuncasting.com or call us 86-18132789710.