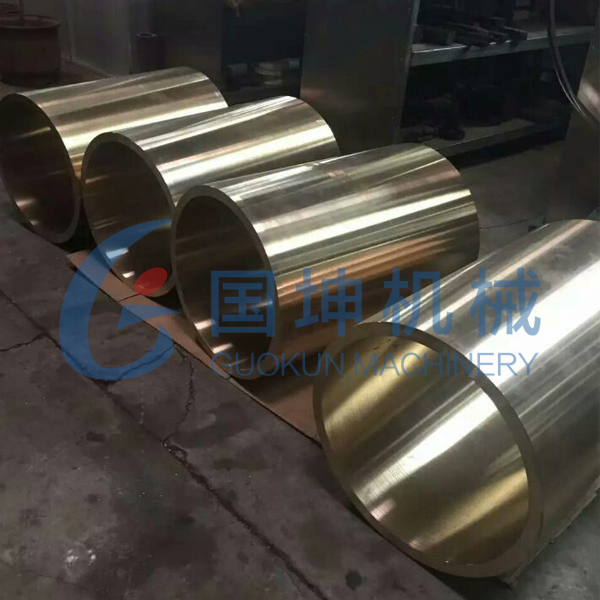

Copper Castings

Baoding Guokun Machinery Co., Ltd and Baoding Guokun Export and Import Trading Co., Ltd are the professional metal casting foundry, company and exporter of various bronze, brass and copper casting components as per your drawings and samples. Most of our copper casting parts are used for crusher, mining parts, valve castings, pump components, industrial hardware, pipe fittings, agricultural equipment parts, oil & gas industry, railroad or railway industry, etc

Our advantages:

- 15 years experience of casting and exporting

- ISO 9001:2008 cetrifaction to control the quality very well

- Testing equipment, Spectrograph, X-ray testing, UT or MT testing, etc

Main information of our casting process

| No. | Centrifugal Casting | Sand Casting | Investment Casting | Precision Machining |

| Process | Centrifugal casting, sometimes called rotocasting, is a metal casting process that uses centrifugal force to form cylindrical parts | Sand casting, the most widely used casting process, utilizes expendable sand molds to form complex, metal parts that can be made of nearly any alloy | Investment casting, also named lost-wax casting, making parts from molten metal. | Precision machining from the tubes, bars, blocks to get the required shapes. |

| Metal | Brass, bronze and copper alloy | steel, brass, copper and copper, cast iron | steel, brass, copper and bronze | steel, brass, copper and bronze, aluminum, etc |

| Weight | Max. 10,000 kgs | Max. 20,000kgs | Max. 500kgs | Max. 10,000 kgs |

| Tolerance | as per drawings | CT9-CT12 | CT4-7 | as per drawings |

| Advantage | Fine inner structure No defects like sand casting |

Can produce complex structure | Complex structure and high production rate | high precision |

So if you have any new inquiry of copper casting components, please email your inquiry to gina@guokuncasting.com or call us via 86-18132789710.

Baoding Guokun Machinery, your good choice of copper casting components!