CNC Lathe Components

Baoding Guokun is China sand casting foundry, investment casting factory and precision machining shop for customized casting components for track, tractor, railway casting, train parts, agriculture or farm machinery, tillage casting, tool casting, marine casting parts, mining, construction machinery, valve or pump castings, pipe fittings according to customer’s drawings or samples.

Lathe machine casting part’s details:

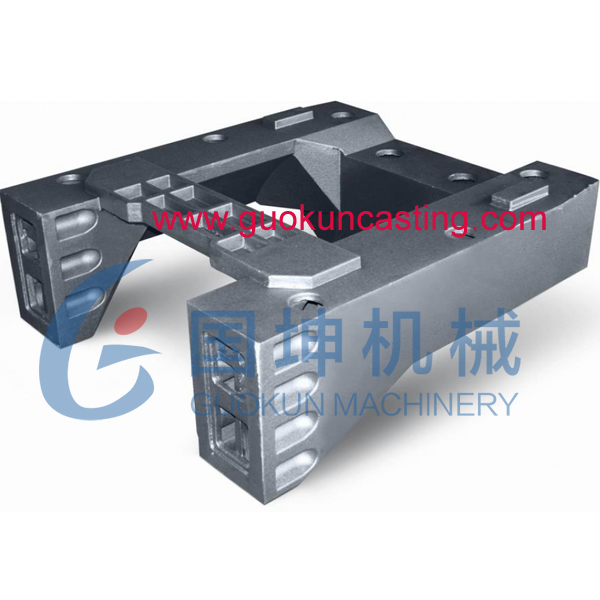

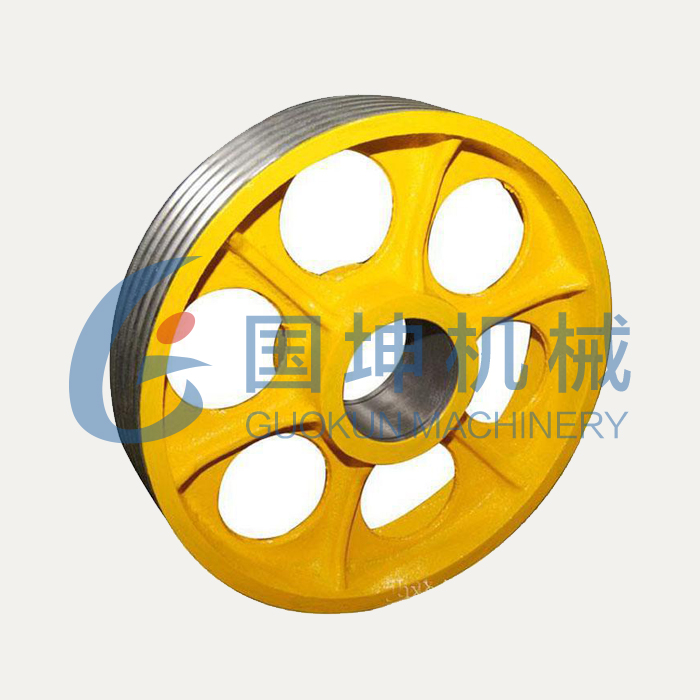

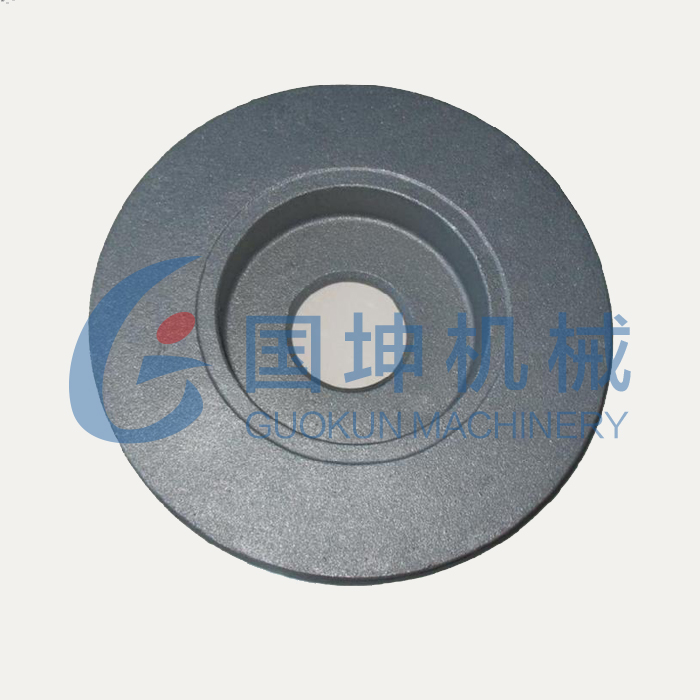

- Part name: lathe machine casting parts, iron casting lathe parts, sand casting lathe components, custom casting lathe parts, customized lathe parts, cast iron lathe bases

- Manufacturing process: sand casting, green sand casting, resin sand casting, shell mold casting, precision machining

- Casting tolerance: CT8-CT12

- Metal: cast iron, grey iron, gray iron, ductile iron, S.C iron

- Weight controlled: Within 25,000 kgs

- Surface treatment: Painting, casting surface

| No. | Centrifugal Casting | Sand Casting | Investment Casting | Precision Machining |

| Process | Centrifugal casting, sometimes called rotocasting, is a metal casting process that uses centrifugal force to form cylindrical parts | Sand casting, the most widely used casting process, utilizes expendable sand molds to form complex, metal parts that can be made of nearly any alloy | Investment casting, also named lost-wax casting, making parts from molten metal. | Precision machining from the tubes, bars, blocks to get the required shapes. |

| Metal | Brass, bronze and copper alloy | steel, brass, copper and copper, cast iron | steel, brass, copper and bronze | steel, brass, copper and bronze, aluminum, etc |

| Weight | Max. 10,000 kgs | Max. 20,000kgs | Max. 500kgs | Max. 10,000 kgs |

| Tolerance | as per drawings | CT9-CT12 | CT4-7 | as per drawings |

| Advantage | Fine inner structure No defects like sand casting |

Can produce complex structure | Complex structure and high production rate | high precision |

Baoding Guokun casting factory have complete quality inspection equipments for dimension testing, mechanical properties and chemical analysis. ISO 9001 certification can help us to issue all quality reports for all inspection. The testing machinery we have is spectrometer, hardness tester, metallographic inspection, tensile strength testing, ultrasonic testing, CMM.

If you need Lathe part casting, iron casting lathe parts, lathe machinery components, CNC Lathe casting, metal casting lathe parts, sand casting lathe parts, lathe parts China factory, Lathe components China company, please mail your inquiry to gina@guokuncasting.com or gina.guokun@gmail.com or call us 86-18132789710.