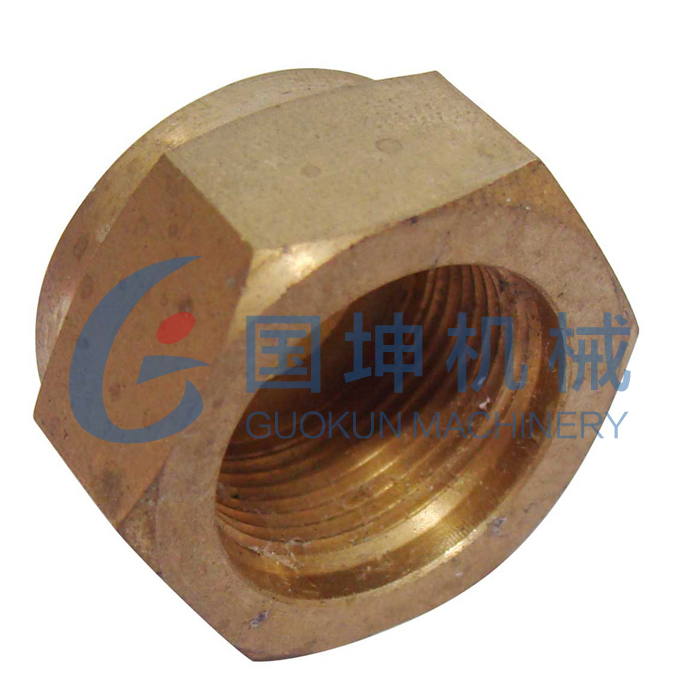

Centrifugal Casting customized parts as per your drawings or required dimensions

Baoding Guokun Machinery Co., Ltd and Baoding Guokun Export and Import Trading Co., Ltd can supply you various centrifugal casting components for crusher, mining, valve & pump castings, metal fittings, hardware, pipe fittings, furniture components, oil & gas industry, lighting spare parts, etc

What’s the centrifugal casting?

Centrifugal casting, sometimes called rotocasting, is a metal casting process that uses centrifugal force to form cylindrical parts. This differs from most metal casting processes, which use gravity or pressure to fill the mold. In centrifugal casting, a permanent mold made from steel, cast iron, or graphite is typically used. However, the use of expendable sand molds is also possible.

Main informtaion for our centrifugal casting process:

- Material: Bronze, NiAl Bronze, Aluminum Bronze, Tin Bronze, High Lead Bronze, brass, cooper, such as C93200, C93800, 9-4-4-2, SAE 67, etc

- Process: Sand casting or centrifugal casting and precision machining as per your drawings

- Capacity: Diameter from 40 mm to 2000 mm; Weight from 0.1 kg to 5000 kgs

- Export to USA, Germany, UK, Finland and all worldwide.

- Mainly products: bearing, bushing, tubes, sleeve, etc