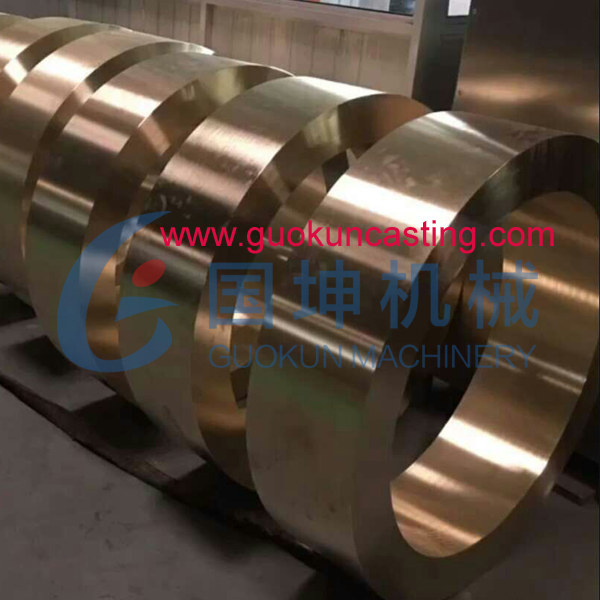

Cast Bronze Bushing, sleeve, bearings

Baoding Guokun Machinery is a professional casted & forged part’s supplier, mainly produce and trade cast bronze bushing, cast bronze flanged bushings, bronze sleeve, bronze thrust washer, bronze bearing, brass bushings, copper bushings which produced by centrifugal casting and precision machining process.

Centrifugal casting or rotocasting method is a metal casting process which the liquid steel is poured into a rotating permanent metal mold and pressed against the outer wall by using centrifugal forces to form cylindrical parts, such as sleeve, bushings, bearings, etc

Centrifugal Casting advantages and disadvantages

| No. | Advantages | Limitation |

| 1 | Higher mechanical properties, strength, ductility, etc | Not all alloys can use centrifugal castings |

| 2 | Finer grain structure | An inaccurate diameter of the inner surfaces. |

| 3 | Less casting defects, shrinkage, voids, properties, etc | Only simple shapes can be casted |

| 4 | Directional solidification that minimizes impurities |

Cast Bronze bushing material

Baoding Guokun Machinery can produce various bronze, brass & copper alloys to be bushings, sleeve, bearings, tubing by centrifugal casting and precision machining, including Leaded Tin Bronzes, Aluminum Bronzes, Manganese Bronzes and No Lead Bronzes.

Centrifugal Casting Bronze sleeve, Cast Bronze bushing manufacturer, supplier, factory, company in China, Baoding Guokun Machinery can assure you high quality and fast lead time. Please send your drawings to gina@guokuncasting.com or call us 86-18132789710.