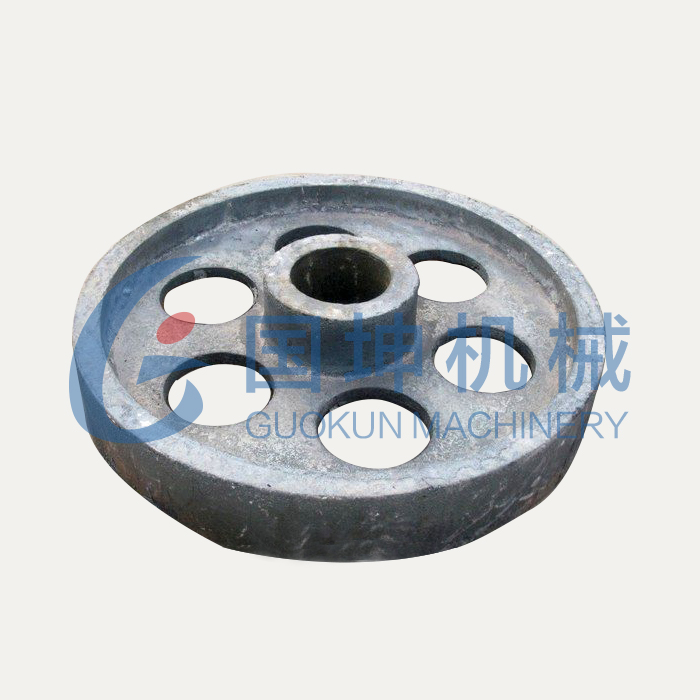

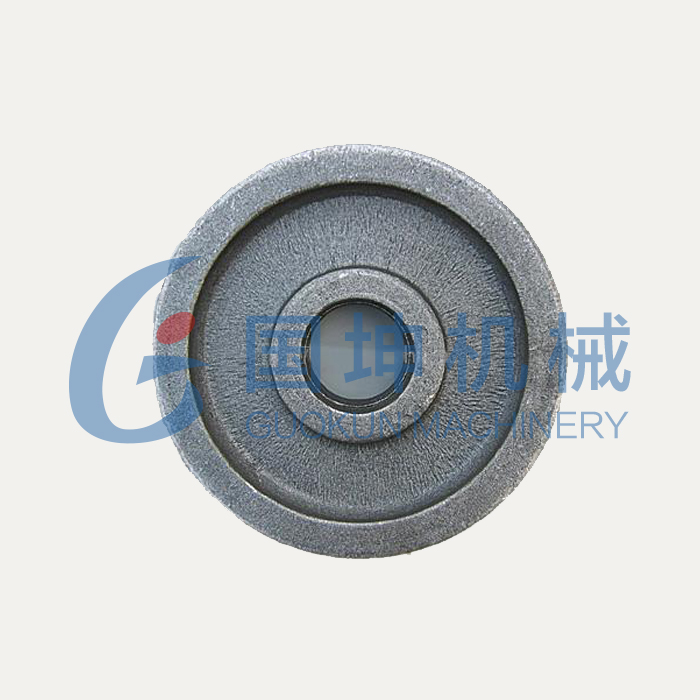

ASTM A48 Grey Iron Casting

Gray iron castings in ASTM A48 Class 20 are intended for general engineering use where tensile strength is a major consideration.

The grade is equivalent with grey irn GB/T 9439-1988 HT150, DIN 1691 GG15, JIS G5501 FC15, NFA32-101 Ft.15D, BS1452 Gr.150, ISO/R185 Gr.15 in China and other countries.

Chemical Composition:

C:3.0~3.6 S:≤0.12 P:<0.15 Mn:0.6~1.0 Si:1.4~2.0

Please note that this chemical composition is not standard, just from working experience of our iron casting foundry.

Mechanical properties

ASTM A48 Class 20 gray iron has a minimum tensile strength of 20,000 psi (140 MPa). Class 20 has a high carbon equivalent and a ferrite matrix.

Grey cast iron ASTM 148 Class 20 can be produced by using the following casting process:

Sand casting

Shell mold casting

Lost foam casting

Shell Mould Casting is an expendable mold casting process that uses a resin covered sand to form the mold. As compared to sand casting, this process has better dimensional accuracy, a higher productivity rate, and lower labor requirements. It is used for small to medium parts that require high precision. Shell mold casting is a metal casting process similar to sand casting, in that molten metal is poured into an expendable mold. However, in shell mold casting, the mold is a thin-walled shell created from applying a sand-resin mixture around a pattern. The pattern, a metal piece in the shape of the desired parts, is reused to form multiple shell molds. A reusable pattern allows for higher production rates, while the disposable molds enable complex geometries to be cast. Shell mold casting requires the use of a metal pattern, oven, sand-resin mixture, dump box, and molten metal.

The custom casting components in ASTM A48 Class 20 are these unimportant casting parts with low duty or load, such as boiler parts, covers, wheel, base plate, weight plate, pump body, valve body, pipe fittings, etc