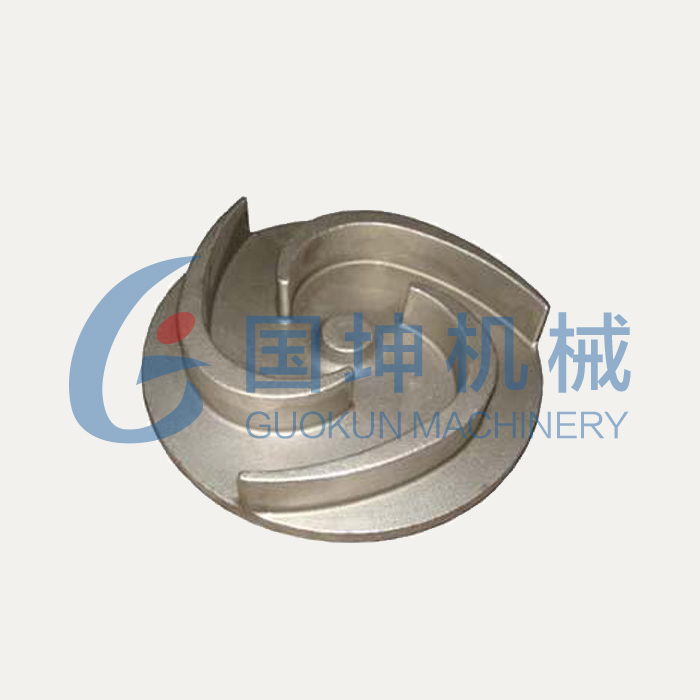

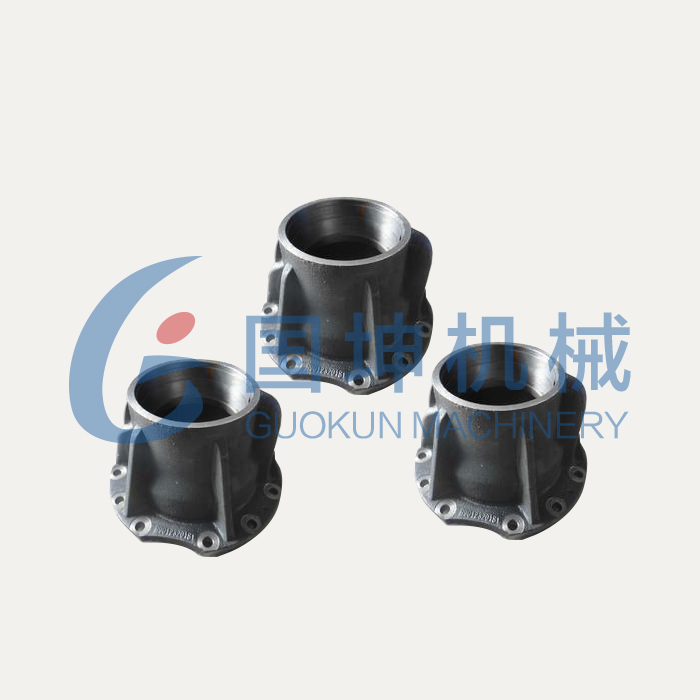

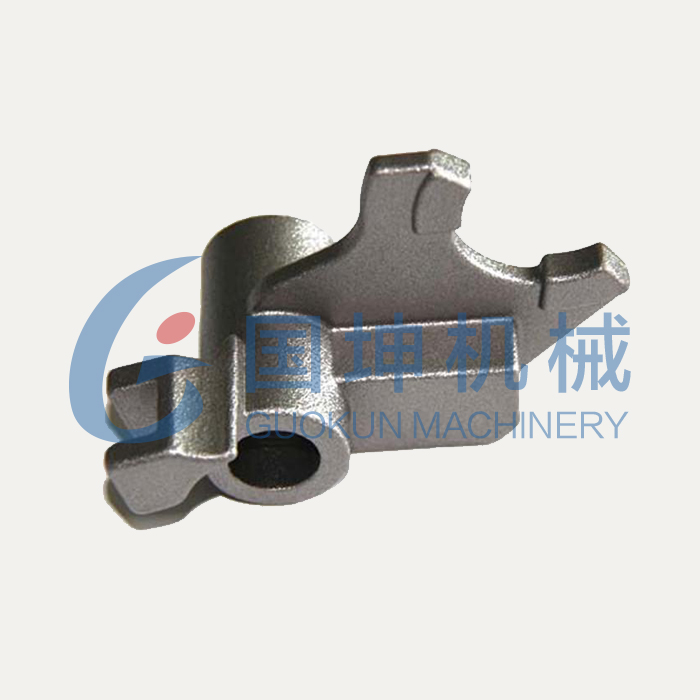

Aluminum casting parts

Guokun Machinery can produce and supply various aluminum casting parts, aluminum sand casting parts, aluminum die casting parts, etc

Aluminum Alloy Characteristics:

- High operating temperatures

- Outstanding corrosion resistance

- Lightweight

- Very good strength and hardness

- Excellent thermal conductivity

- High electrical conductivity

Aluminum die casting

Die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mold cavity. Aluminum die casting is with lightweight, high dimensional stability for complex shape and thin walls; good corrosion resistance; good mechanical properties; excellent thermal and electrical conductivity; retains strength at high temperatures.

Aluminum alloy: 413, 383, B390, A360, A380, A413

Advantage of aluminum die casting process

- Excellent dimensional accuracy

- Smooth cast surfaces

- Thinner walls can be cast as compared to sand and permanent mold casting

- Reduces or eliminates secondary machining operations.

- Rapid production rates

- Casting tensile strength as high as high as 60ksi

- Casting of low fluidity metals

Aluminum sand casting

Sand casting, also know as sand molded casting, is a metal casting process characterized by using sand as the mold material.

Please send us the drawings to gina@guokuncasting.com or gina.guokun@gmail.com