Investment Castings China Foundry, manufacturer, company of steel investment castings, stainless steel investment casting, lost wax investment casting, precision investment castings, OEM investment casting parts with high quality and competitive prices.

Baoding Guokun Machinery and Baoding Guokun Export and Import Trading Co., Ltd is the professional alloy casting foundry and trader of investment casting, water glass casting, silica sol casting and precision casting parts in low volume or large volume.

What is investment castings?

Investment casting process or precision investment castings, also named lost-wax casting, making parts from molten metal, usually carbon steel, alloy steel, stainless steel, special steel, aluminum, brass and copper, etc.

Usually we offer two different investment casting process, water glass casting and silica sol casting process.

Investment casting process

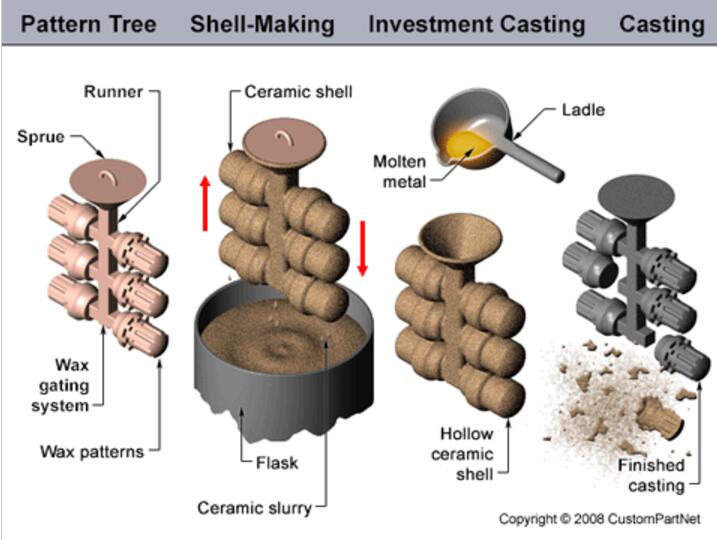

The investment casting process consists of several steps: metal die construction, wax pattern production, ceramic mold creation, pouring, Cooling, casting removal, and finishing.

Investment casting advantages or benefits

- Almost any metal can be casted, such as stainless steel, carbon steel, alloy steel, wear-resistant steel, aluminum alloys, bronze alloys, brass alloy investment casting, alloy castings, zinc investment casting, etc

- Excellent Surface Finish: 50-125 uin, much better than sand casting process

- High Dimensional Accuracy: Water glass casting process’s tolerance: CT6-8; The casting tolerance for silica sol casting process is CT4-6

- NO flash or parting lines: Compared with Hot forging or drop forging process, the precision investment casting process is without no flash and parting lines.

- Little need for secondary machining

- Can produce complex shapes

Investment Casting Defects

The common defects of precision investment casting are sand hole, gas cavity, shrinlage cavity, sand burning, burrs, insufficient pouring, etc. But Baoding Guokun Machinery has more than 15 years of casting experiences to avoid such above defects.

Investment casting materials

- Alloy Steel Investment castings: 4140, 4340, 42CrMo, etc

- Carbon Steel Investment casting: 1045, 1035, etc

- Stainless steel investment casting: 304, 316, 17-4 PH

- Bronze, brass or copper alloy investment castings

- Aluminum, zinc alloy

Investment casting applications:

The industry investment casting served is valve and pipe fittings, agricultural parts, automobile & truck parts, mining casting parts, oil & gas industry, municipal engineering, train & hsr parts, marine parts, furniture components, power electronic parts, etc

Please send your drawings and requirements to gina@guokuncasting.com or call us 86-18132789710 ( WhatsApp).