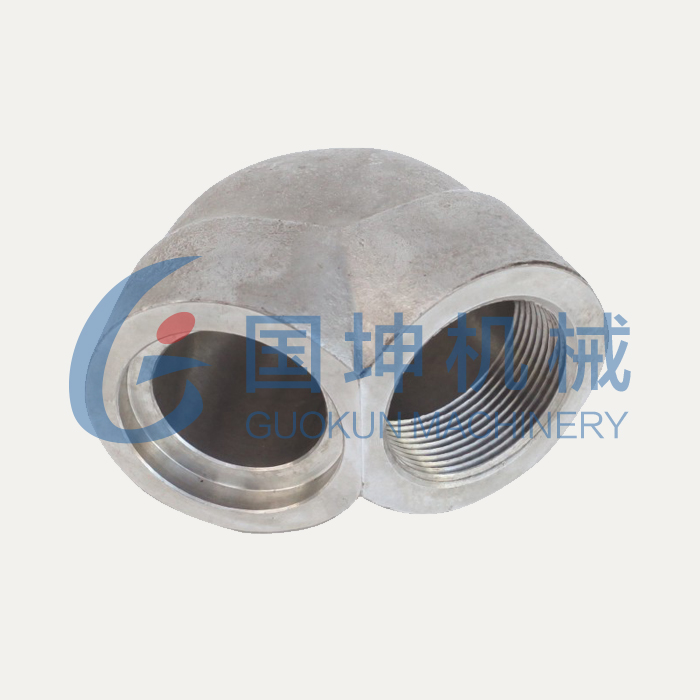

Centrifugal Pump Impeller

Guokun Casting is a global leader in the production of highly engineered investment casting, lost wax casting parts, sand casting parts, die casting parts in carbon steel, low/medium alloy steel castings, stainless steel casting, wear resistant steel casting, gray iron, ductile iron, used for Mining, Agricultural, Industrial, valve and pipe fittings, Rail components, Automobile, bus and truck parts, etc

Quality Control:

Guokun production System

Chemical Testing

Mechanical Testing

Metallographic Testing

Magnetic Particle Testing

Ultrasonic Testing

X-ray Testing

ISO 9001:2008

Why choose us?

1.The ability to provide low and high volume runs in both rough and finished steel castings, meeting all our customer’s needs.

2.We operate a state-the-art, technology-driven engineering and manufacturing facility based in Baoding, some many famous related casting foundry, machining shop, surface treatment factory around us.

3.Each of our customer’s concerns regarding cost, quality, and on-time delivery are our concerns and every effort is made to make sure our customers expectations are meet or exceeded.

4.Customer operations can benefit from improved equipment wear life, with lower processing costs as result.

Details:

1.Material:Carbon steel, alloy steel, stainless steel, wear resistant steel casting, gray iron, ductile iron, nodular iron, malleabe iron, aluminum casting, brass or bronze, etc

2.Casting process:

(1).Sand casting, resin sand casting, green sand casting

(2).Investment casting, Lost wax casting or precision casting, water glass casting, silica sol casting

(3).Die casting

(4).Permanent casting, gravity casting

(5).Low pressure casting

(6).Centrifugal casting

3.Machining process: Machined casting parts, machined forging parts, rough machining or precision machining, CNC turning, milling, drilling, tapping, grinding, boring parts

4.Application: Food processing parts, Sporting Equipment, Mining casting parts, Pipe fittings & pump parts, Automobile, truck, bus parts, Oil & gas casting, manhole covers and frames, casting latch …..

5.Heat Treatment: Normalizing, Tempering, Quenchining

6.Surface Treatment: Polishing, Plating, Painting, Anodizing, Powder coating, sand blasting

7.Dimension Tolerance: CT5-CT13, machining tolerance as per drawing

8.Packaging: Wooden case